Rotary screen printing cape town.

Rotary screen printing process pdf.

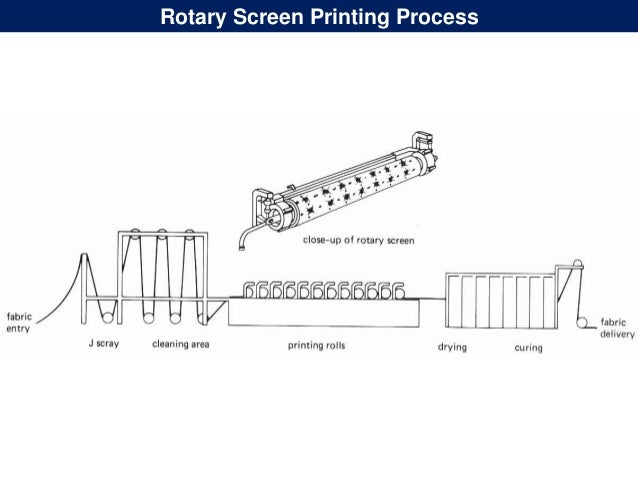

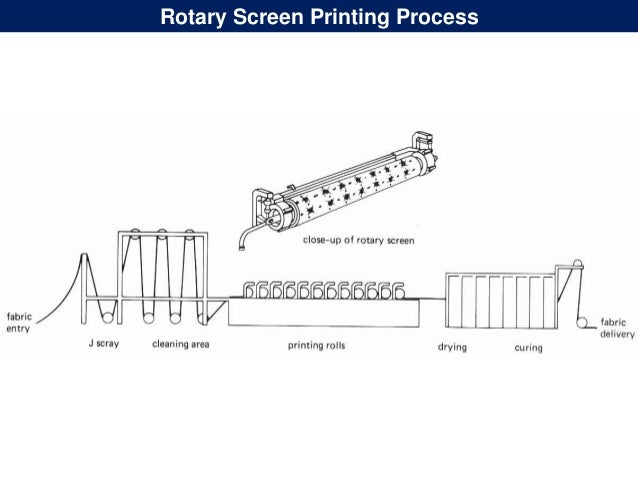

The machine employs a rotary screen for each color as in flat screen printing and the design for each rotary screen is made in a manner similar to automatic flat screen printing.

Screens have to be cut and made to the design we require and each colour way has to be.

Performance rating was obtained using the speed rating technique.

Screen printing is an analogue process that we have been operating and specialising in for over 30 years.

Self check questions fig 11 6 fully automated flat screen printing machine fig 11 7 rotary screen printing set up fig 11 8 rotary screen printing section.

In rotary screen printing for every colour there is a screen a supply system for the colour and a paint kitchen inventory.

O ecotextiles stated in 2012 that estimates indicate that this technique controls approximately 65 of the printed fabric market worldwide 1 here are 5 reasons why.

By converting the screen printing process from semi continuous to continuous higher production speeds are obtained.

The standard time for the printing operaton on the octrooi aangev raagd rotary screen p rinting machine for 3 cycles.

A printing machine that utilizes seamless cylindrical screens made of metal foil was originally developed in holland.

Typical speeds are from 50 120 ypm 45 100 mpm for rotary screen printing depending upon design complexity and fabric construction.

As a result considerable amounts of dye paste end up in the wastewater because the volume of the machines is significant and a substantial quantity of.

This process is called rotary screen printing.

The screen printing method entails first splitting the image into separate colours a screen is then created for each colour.

Prepare a 8 x8 design for screen printing process.

We have the flat screen hand printing method and or the rotary cylinder machine.

The print finish quality of rotary screen printing is not to the same standard as modern day discharge printing machines.

Rotary screen printing is also related with piece decorating applications where individual sheets of substrate are printed one by one usually on semi and three quarter automatic flatbed presses that.

It is often carried out as a large scaleindustrial process and is an essential part ofpublishing d n a transaction printing.

After print application the process is the same as flat screen printing.

Rotary screen printing offers stunning print quality on a variety of substrates.

The rotary screen printing machine is fast but limited to the designs it can print and commercially very economical way of printing.

Today there are many options for printing but rotary screen printing still leads the market.

Fact rotary screen printing uses precision cut.